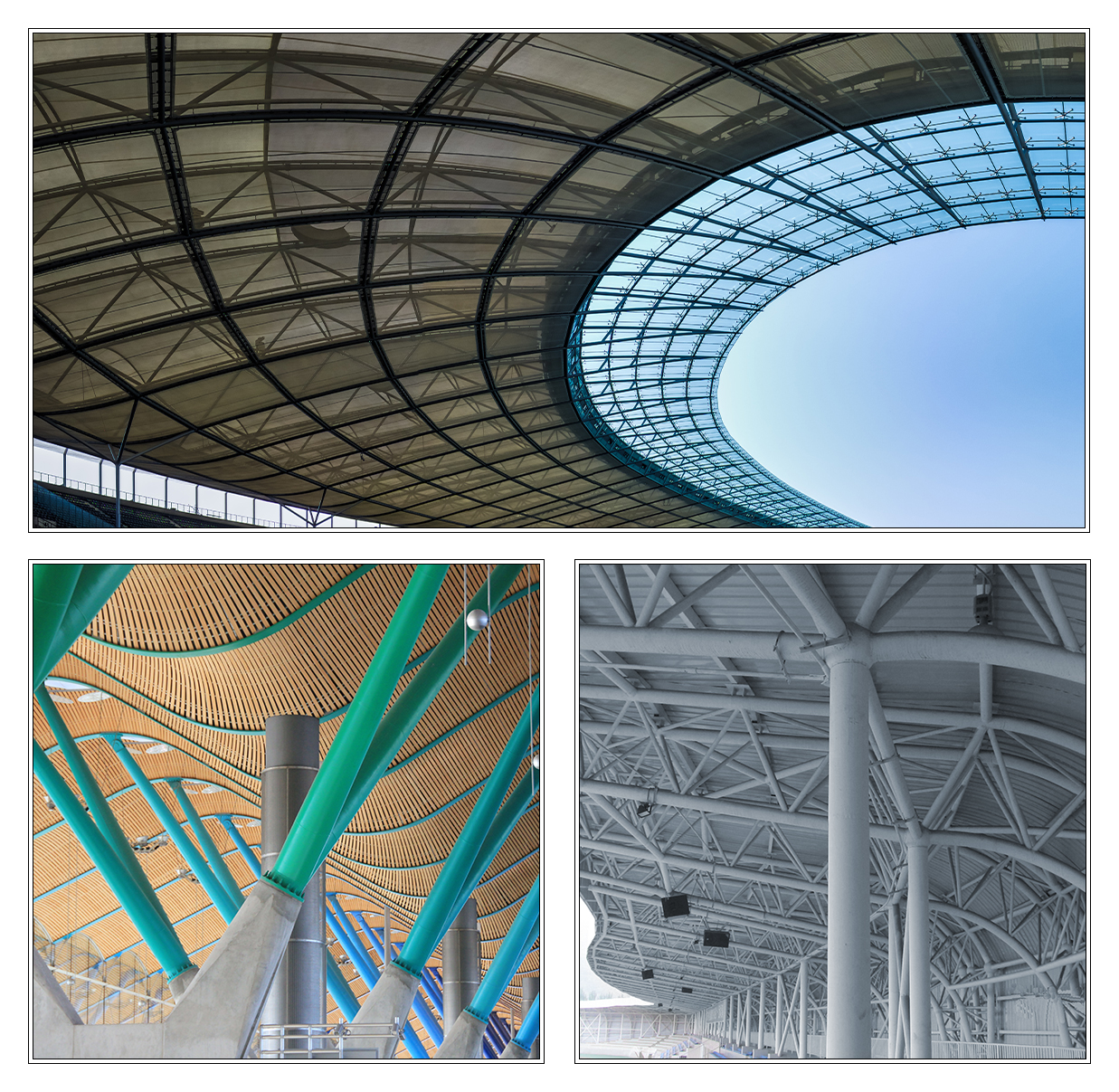

Space Frame Steel Truss Stadium Steel Structure & Steel Roof Structure

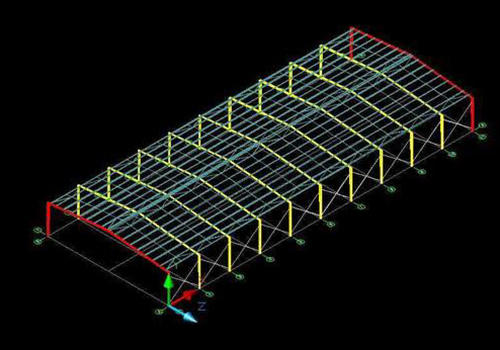

Characteristics of truss structure

The truss is composed of steel tubes, strong carrying capacity in cross section and the cross section can be bent to curve modeling. Beautiful appearance, simple internal space, often used in public buildin

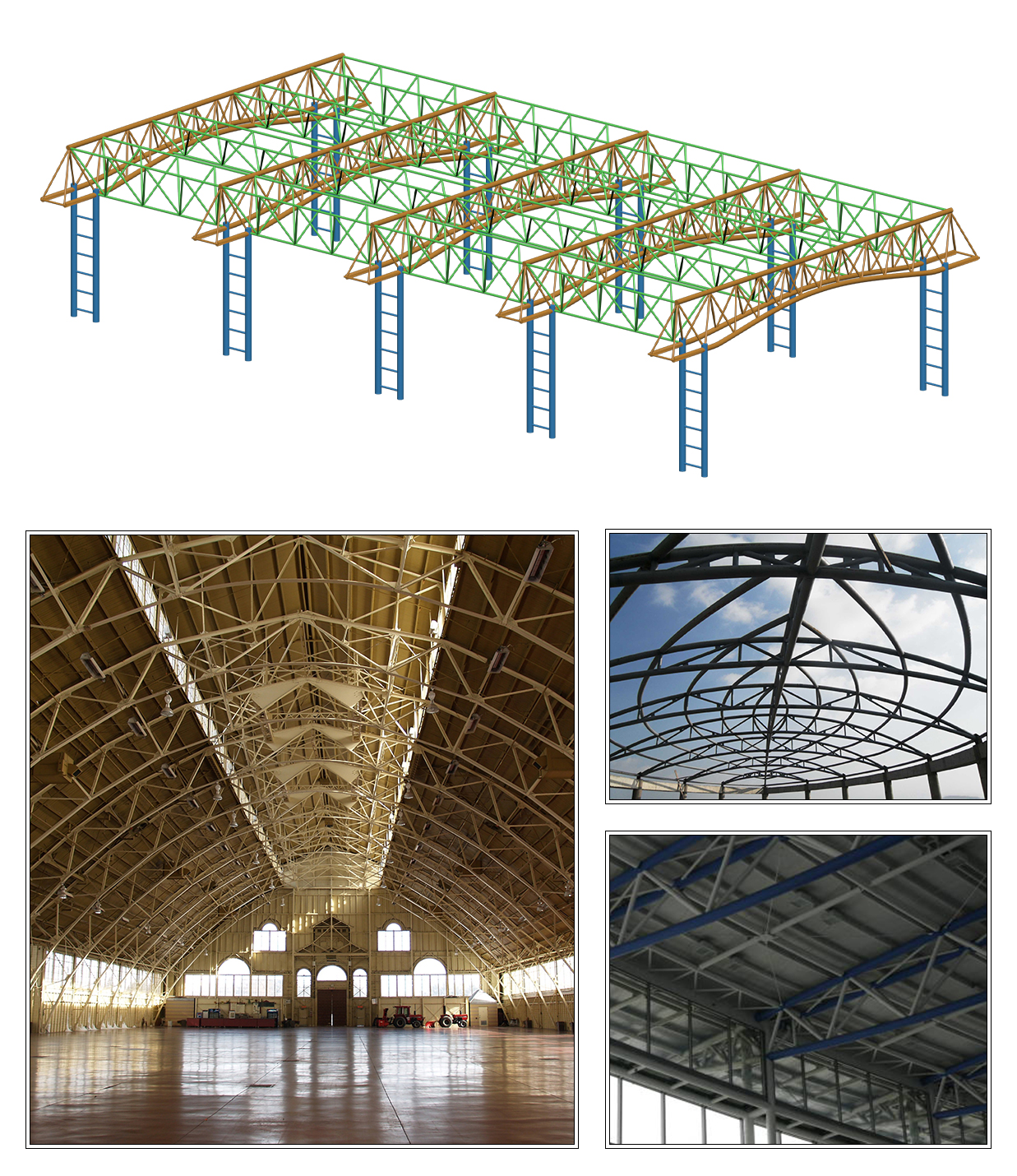

Stress of truss structure

Truss is actually a plane stress system, similar to frame structure, each stress plane system is connected through the longitudinal truss, as a longitudinal support, and also ensure the overall stability of the truss

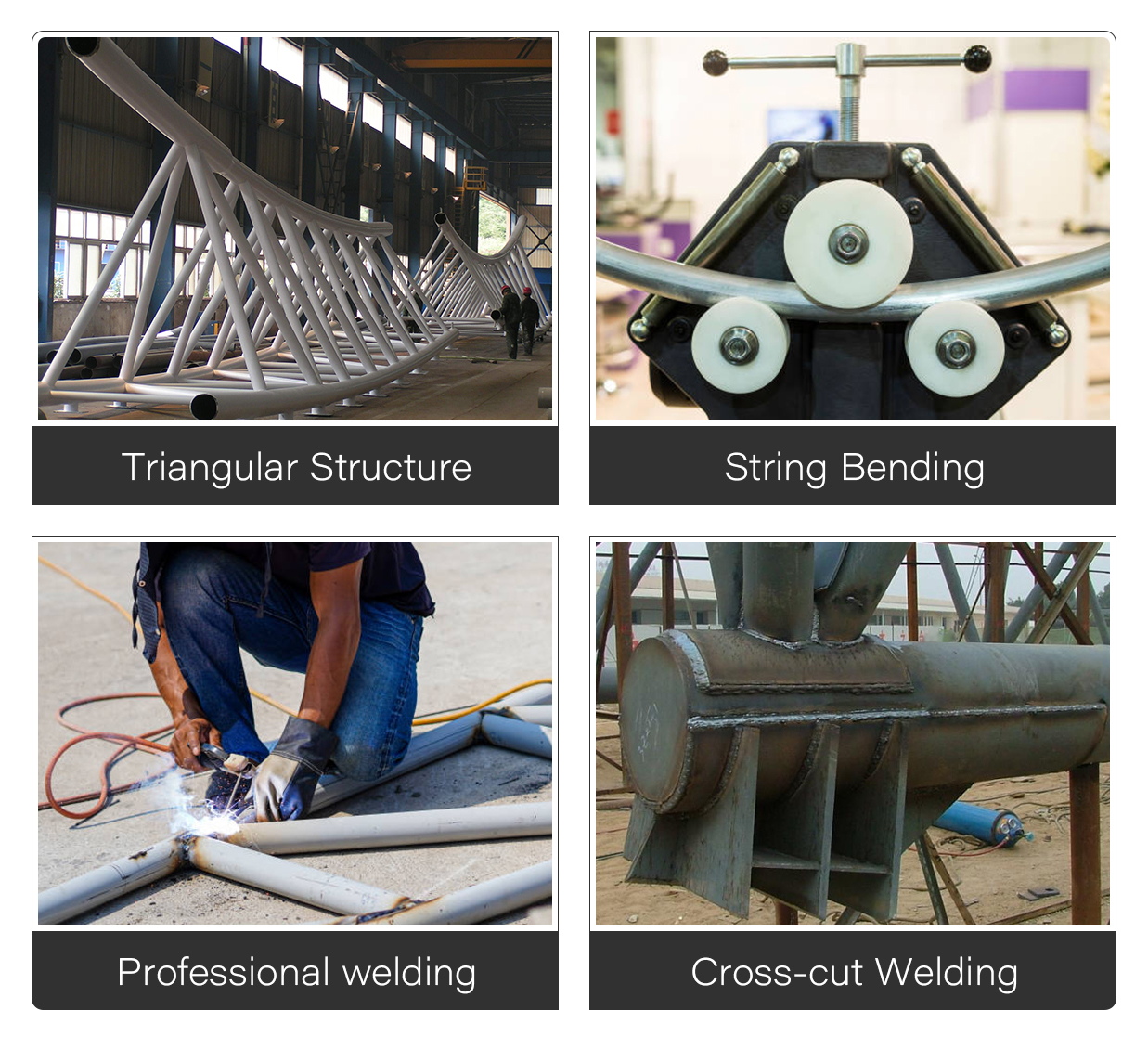

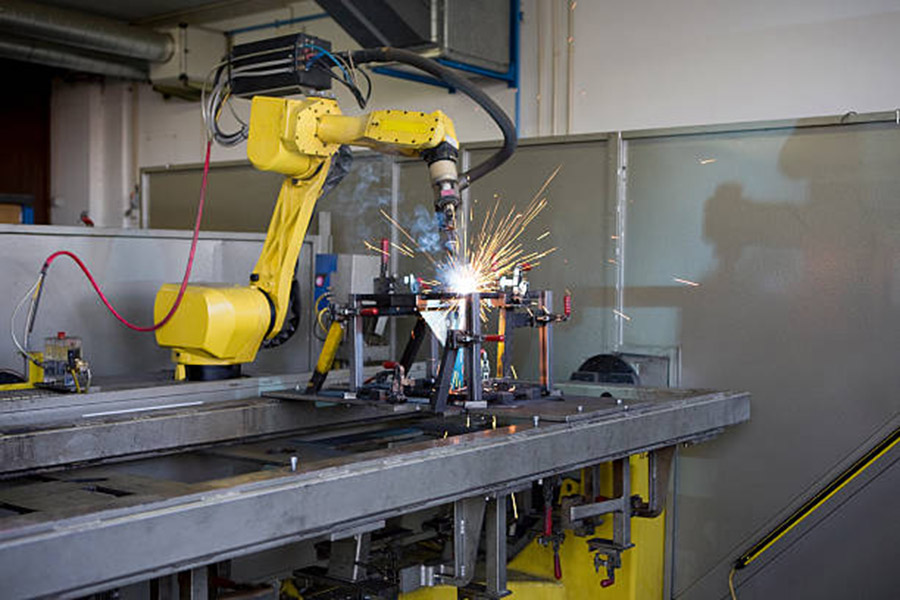

Fabrication of truss structure

Trusses usually use triangular section, which makes the trusses have better rigidity in both directions and is convenient for production

The girdle of the truss and the chord are connected by intersecting line cutting and welding, and the chord must be bent into the curved shape required by the design in advance.

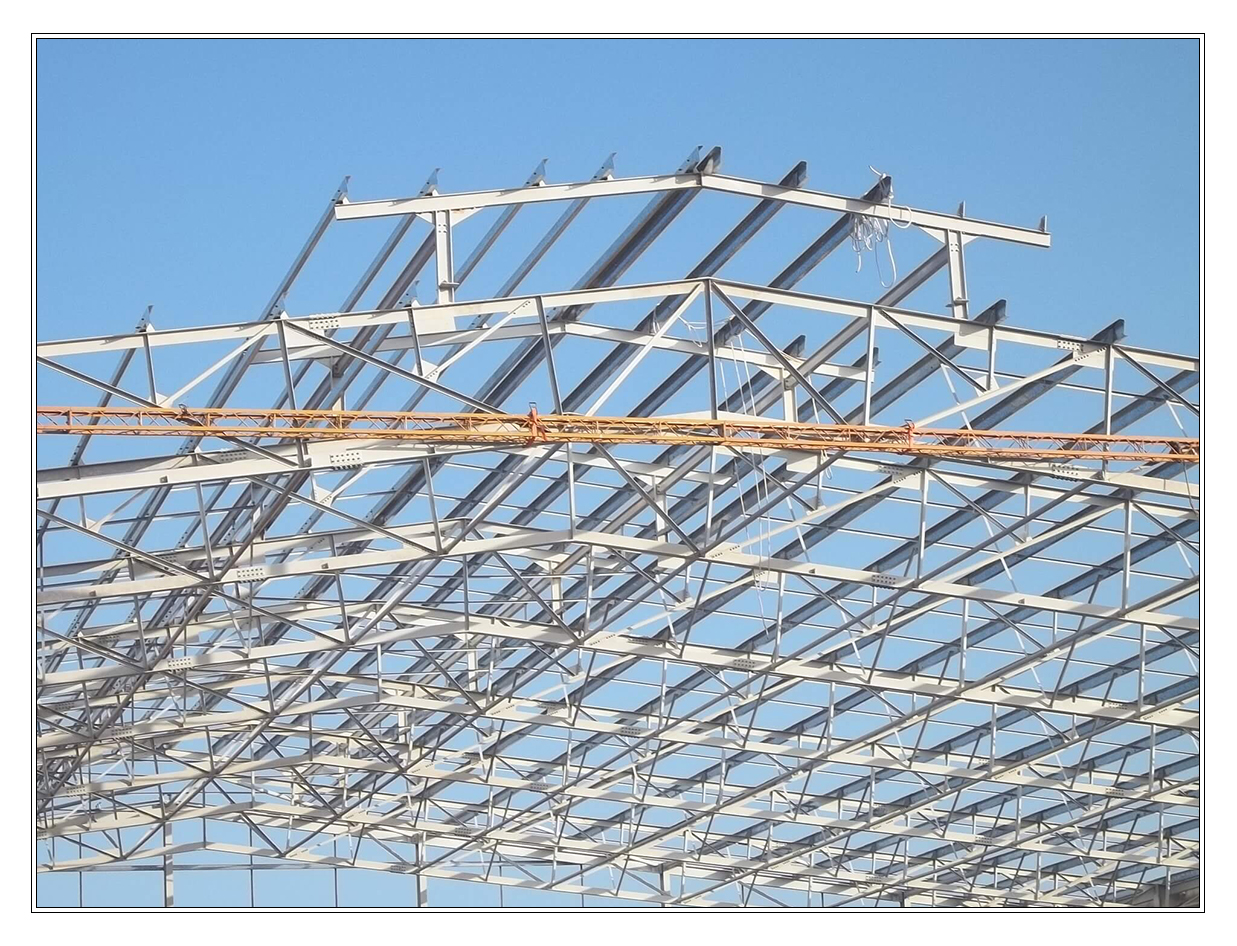

Site assembling of truss structure

The truss section are usually large, the components are too wide to be transported and very uneconomical, in hence, all the truss are welded on the site and heavy workload on site

Truss is large span and heavy component, it’s generally constructed on the floor when used in public buildings such as airports and exhibitions. Large machinery is not allowed to enter into, other types of spatial structure construction is basically limited by site conditions, so the construction is more complex, site lifting, welding workload is large.

Commonly used pipe truss construction methods include large mechanical lifting, high altitude bulk, high altitude sliding, integral lifting and so on.

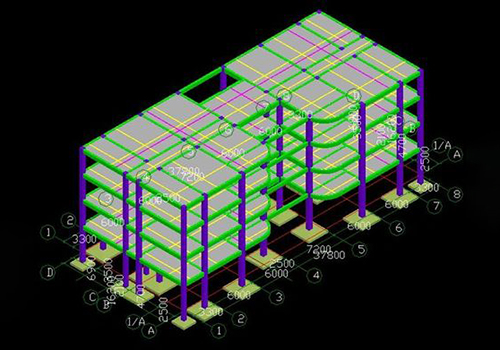

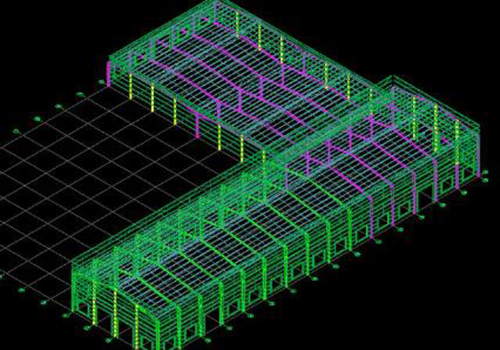

Free Customized Design

We design complex industrial buildings for clients using AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures(Xsteel)and etc.

Main products

Steel Prefab Warehouse

Steel Prefab Hangar

Steel Prefab Stadium

Bailey Bridge

Station

Exhibition Hall

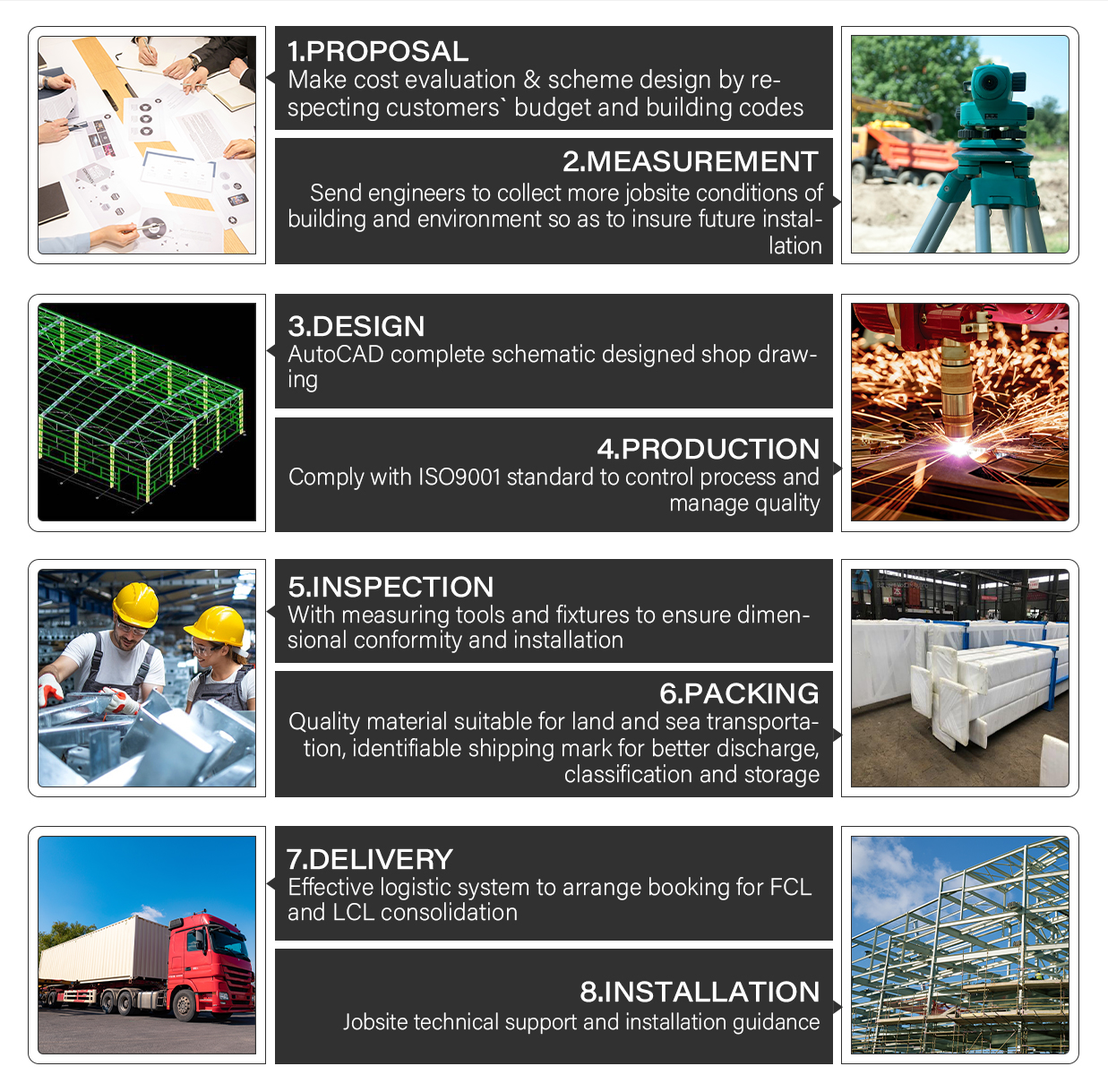

Customization process

Production Workshop Overview

Iron Workshop

Raw Material Zone 1

Aluminum alloy workshop

Raw Material Zone 2

Automatic Spraying Area

Multiple cutting machines

Production Process

1.Prepare Material

2.Cutting

3.Joint

4.Automatic Sub-merged Arc welding

5.Straightening

6.Parts Welding

7.Blasting

8.Coating

Quality Control

Thickness detection

Ultrasonic welding inspection

Spray paint inspection

Welding inspection

Packaging & shipping

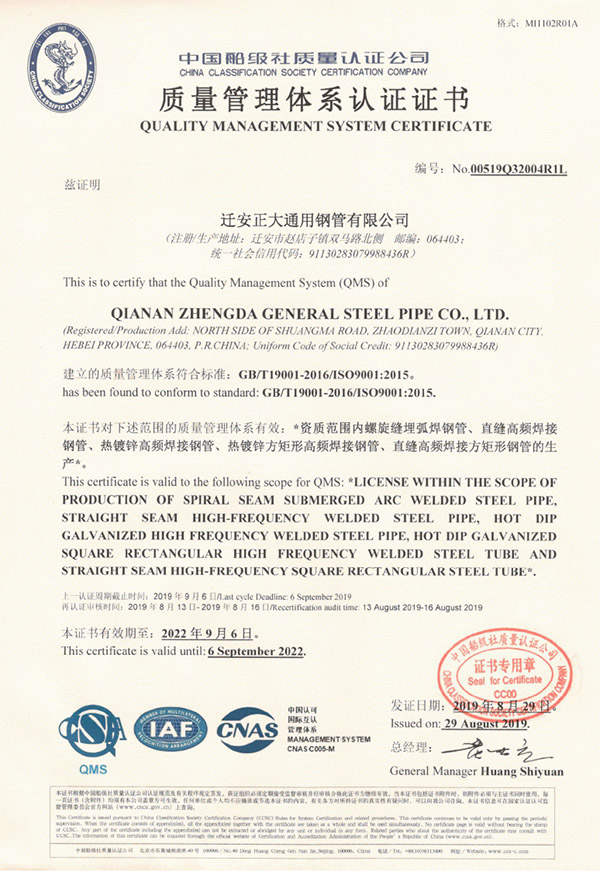

Certification authority

FAQ

Q: Do you supply installation service?

A: Yes, we do. But you will pay for our professional installation cost at your local place, then we will send the engineers to supervise it.

Q: How long can the frame be used?

A: The use life of the main structure is the designed used life, usually is 50-100 years (standard request of GB)

Q: How long is the use life of the roof cover?

A: The use life of the PE coating is usually 10-25 years. The use life of roof sun light sheet is shorter, usually 8-15 years.

Q: What is the anti-rust treatment for steel structure?

A: Anti-rust treatment of steel structure

Normal anti-rust paint

Anti-rust paint with epoxy zinc primer

Hot-dip galvanization

Hop-dip galvanization + PU finish

Powder coating

Stainless steel structure: No. 301/304/316 stainless steel structure.

Q: How do we cooperate on certain project?

A: Firstly, please send us your project details and your requirements. Then we will design accordingly, free of charge.

Afterwards, please check and confirm whether you like the drawings. If not, we shall get the drawings revised until your confirmation. Finally we make a deal.

Get the Price

Please kindly inform us of the information below if you are interested in our products.

1. Usage: For warehouse, workshop, showroom and etc.

2. Location: Which country or area?

3. Size: Length*width*height (mm)

4. Wind load: max Wind speed (kn/m2, km/h, m/s)

5. Snow load: max Snow height (kn/m2, mm)

6. Anti-earthquake level?

7. Brick wall needed or not?

If yes, 1.2m high or 1.5m high

8. Thermal insulation needed or not?

If yes, EPS, fiberglass wool, rock wool, PU sandwich panels will be suggested.

If not, the metal steel sheets will be more affordable.

9. Quantity (unit) and size (width*height) of doors and windows.

10. Crane needed or not?

If yes, quantity (units), max Lifting weight (tons), max Lifting height (m).

Cooperative company