Unitized Glass Curtain Wall System External Wall Design Proposal Overseas Installation Deshion Construction Contractor

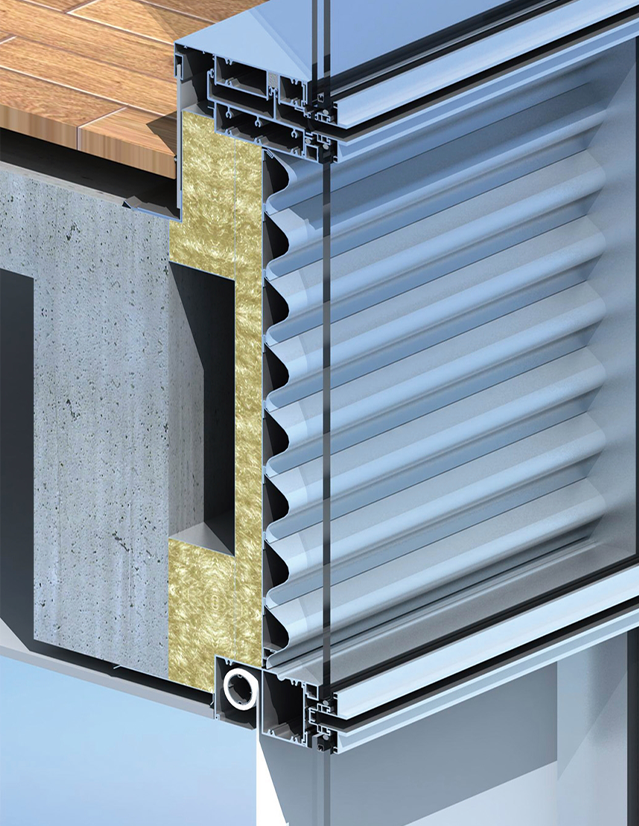

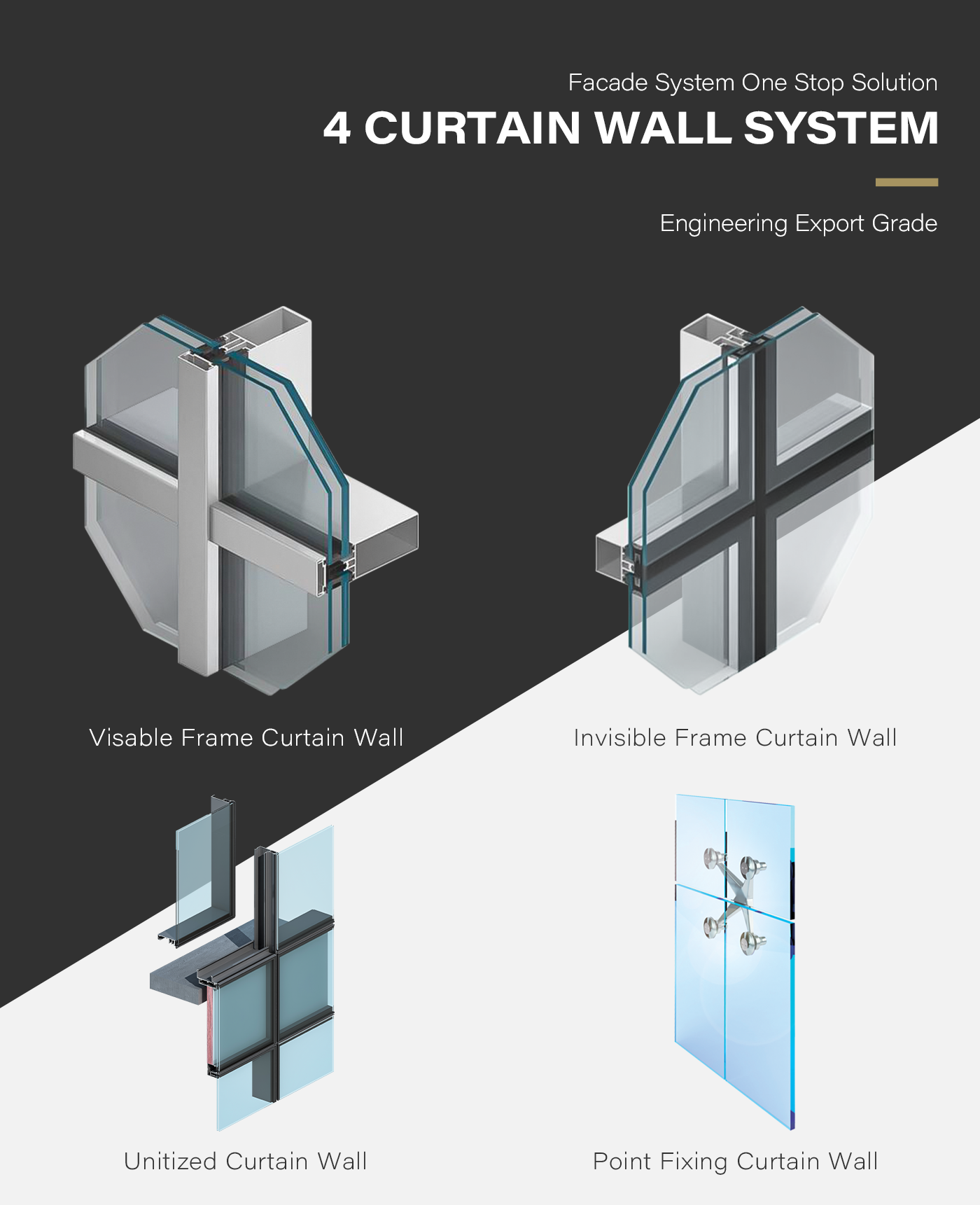

Characteristics of unitized curtain wall

The main factors leading to the deflection of the main structure of civil construction are: the construction error of civil construction, the uneven settlement, the existence of microseismic after use, deformation in the earthquake. The unitized curtain wall is inserted through the slots between each adjacent plate and has good expansion and deformation capacity

Each unit plate of the unitized curtain wall is a whole, so the relative displacement of each unit component is extremely small, and the integrity of the plate can still be guaranteed after the expansion and deformation reset.

Since the unit body is assembled in the factory and can be installed directly after being transported to the site, without occupying a lot of space on the site and only accounts for about 30% of the stick curtain wall, which avoids long-term stacking and effectively reduces the loss rate of semi-finished products.

Characteristics of unitized exposed frame curtain wall, unitized hidden frame curtain wall, unitized half-hidden frame curtain wall

|

01 |

Unit plates are all completed in the factory workshop with high assembly accuracy. |

|

02 |

Fast installation speed, short construction period, easy to protect finished products. |

|

03 |

It can be constructed synchronously with the main structure of civil construction, which is beneficial to shorten the whole construction period. |

|

04 |

The structure adopts the principle of decompression step by step, and the drainage system is set inside, which has good performance of preventing rain seepage and air infiltration. |

|

05 |

Plate joints are all sealed with special aging resistant rubber strips, which makes the curtain wall has self-cleaning function and the surface is less polluted. |

|

06 |

The plates are connected by plate grafting, with strong seismic capacity |

Independent units glass curtain wall

|

Standard products |

It can be installed and disassembly freely |

|

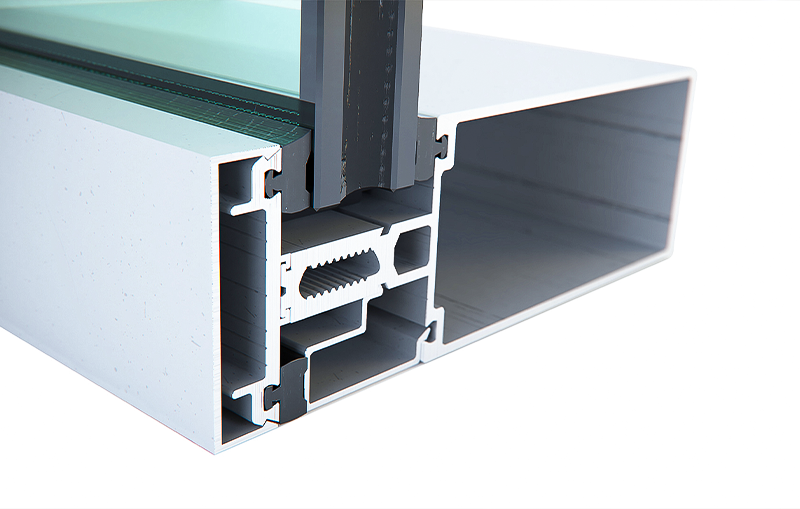

Structure features |

The glass is mainly subjected to wind pressure by the hook plate on the four sides. The design of structural sealant makes the structure have double safety protection function |

|

Architectural effect |

The outer line of sight is concise and lively, with good permeability |

|

Application |

It can achieve large partition plate, which is suitable for airport, exhibition hall and other huge building |

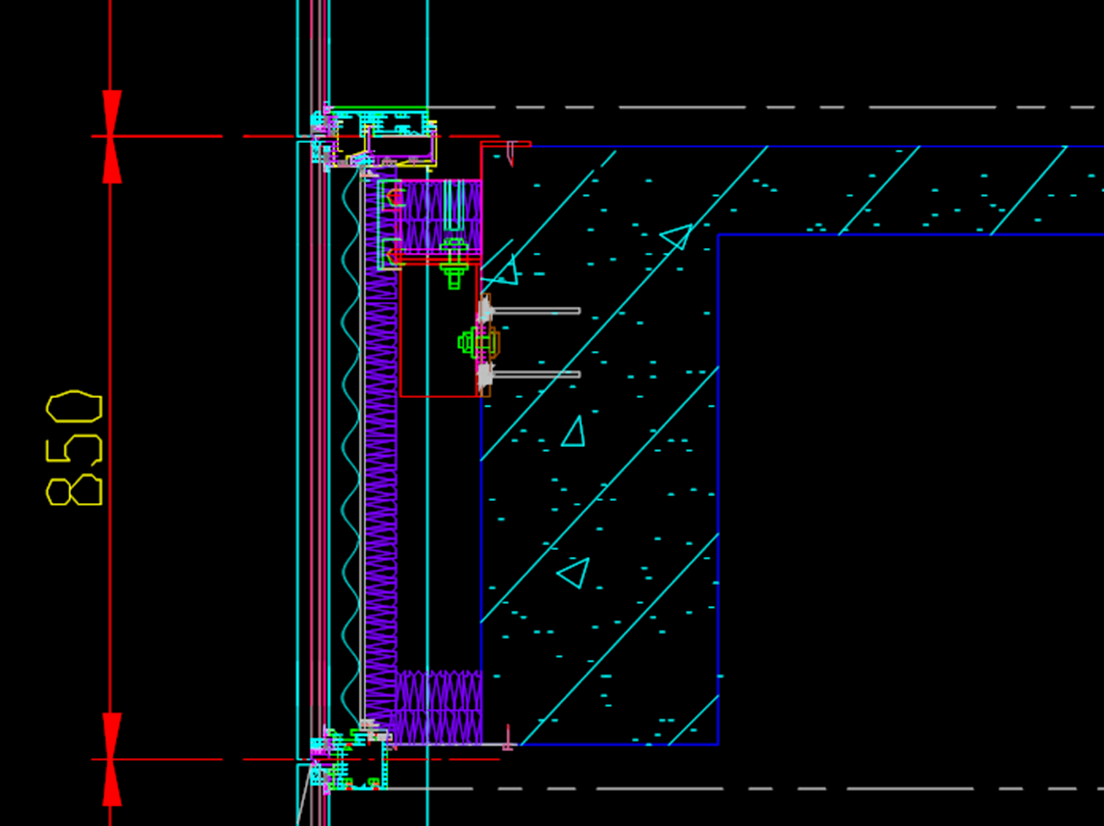

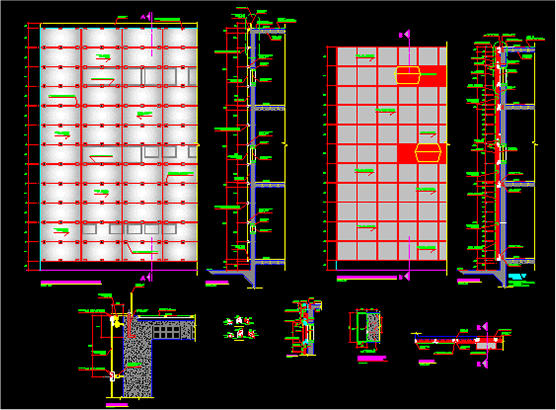

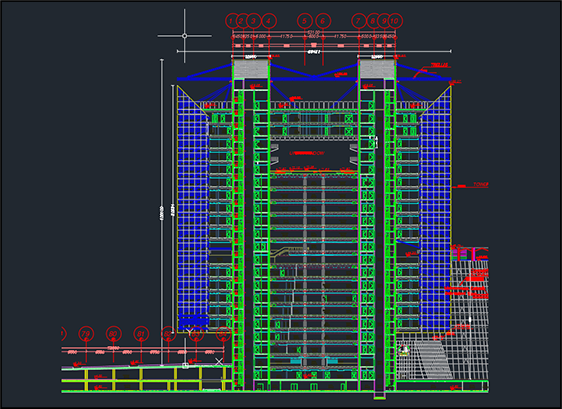

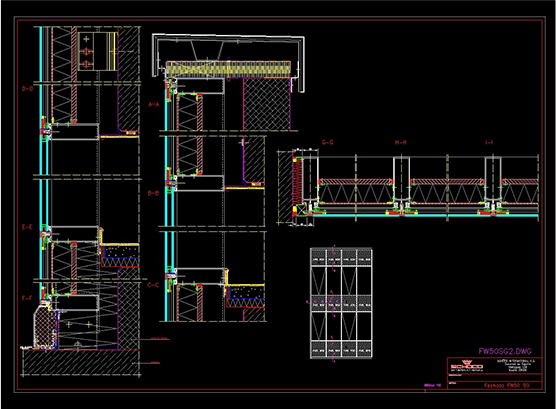

Composition principle

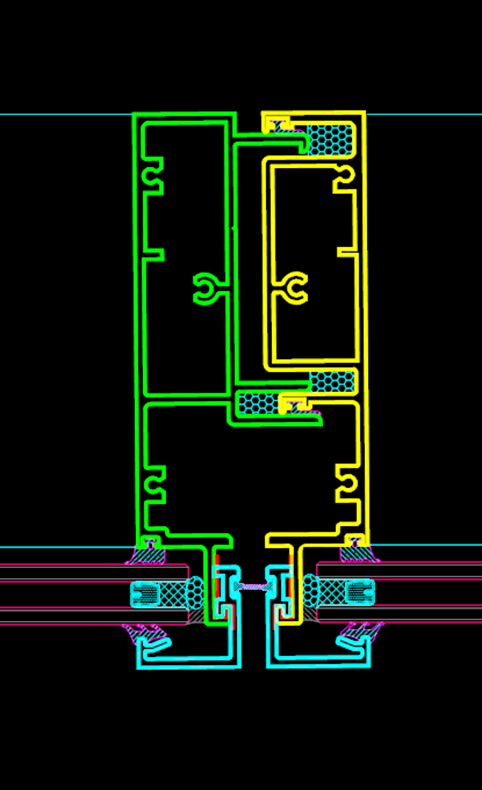

1.assemble each element (mullion, horizontal frame) into unit component frame in the factory, and install curtain wall panel (glass, aluminum plate, stone, etc.) on the corresponding position of unit component frame to form element composites.

2.Transport the component assembly to the site and directly fix it on the main structure by hoisting.

3.The upper and lower frames (left and right frames) of each unit component are inserted to form a combination rod and complete the joints between the unit components, eventually form the whole curtain wall.

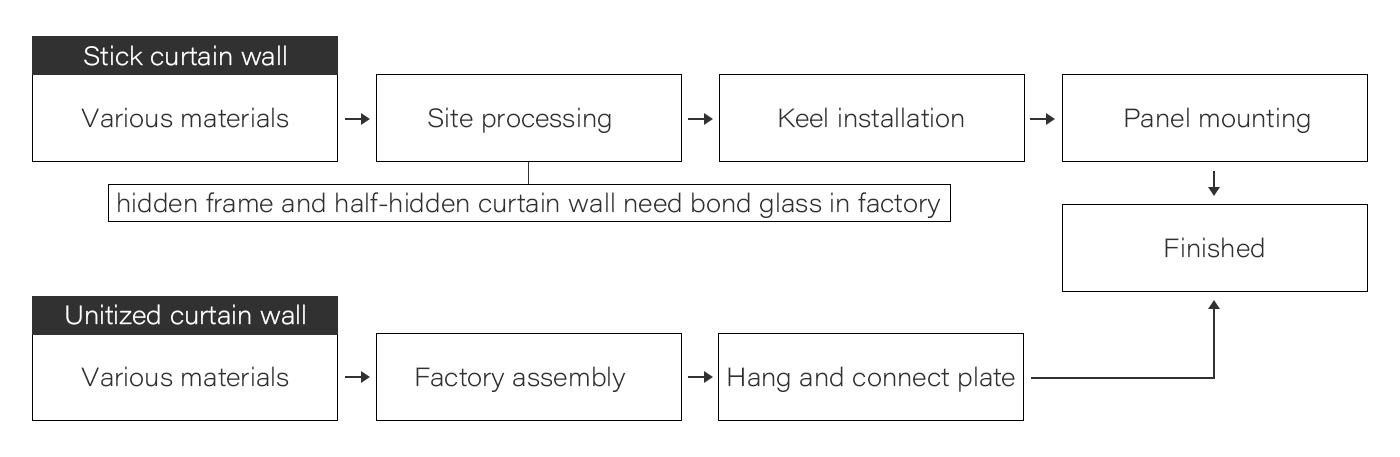

Stick and unitized curtain wall flow chart

Unitized curtain wall lifting

Stick curtain wall installation

Unitized curtain wall lifting

Stick curtain wall installation

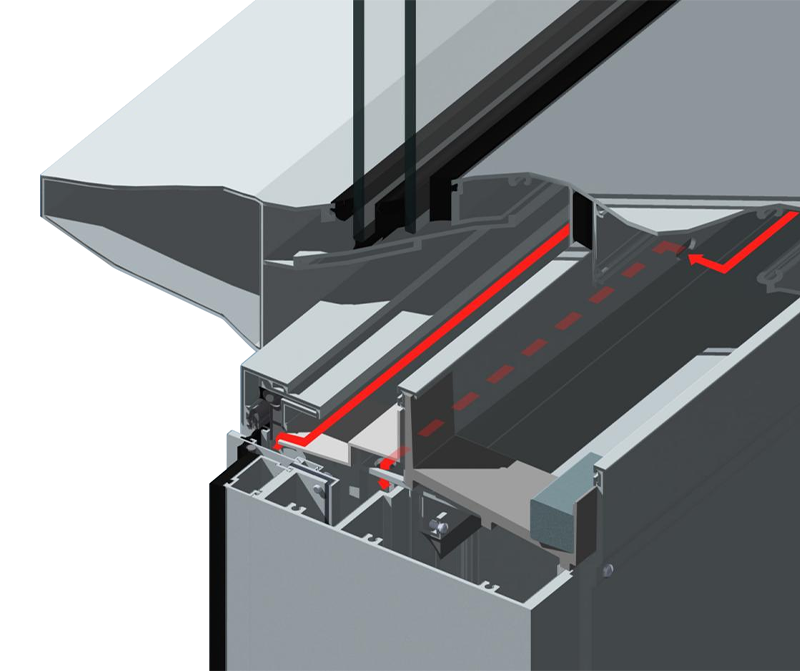

Waterproof performance

Drainage direction

*Unitized curtain wall adopts "isobaric principle", waterproof performance is good

Insulation design of unitized curtain wall

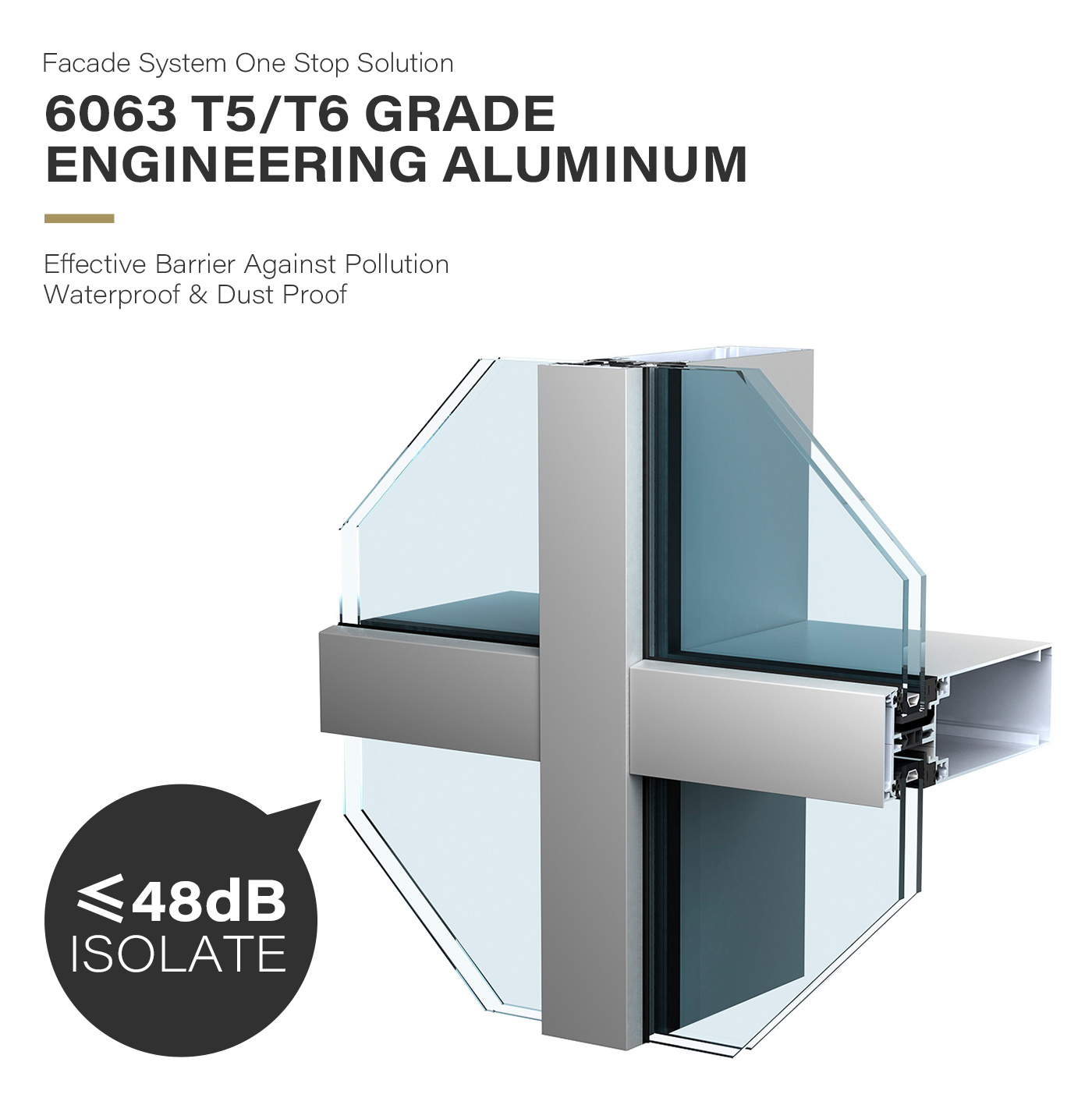

Curtain wall and glass testing

Curtain wall with lighting function requirements, the transmittance reduction factor should not be less than 0.45. Curtain wall with color discrimination requirements, its color perspective index should not be lower than Ra80

The curtain wall shall be able to support its own weight and the weight of various accessories in the design, and can be reliably transferred to the main structure

The maximum deflection of the horizontal stressed member within the span at both ends of a single panel under standard dead weight should not exceed 1/500 of the span at both ends of the panel, and not exceed 3mm

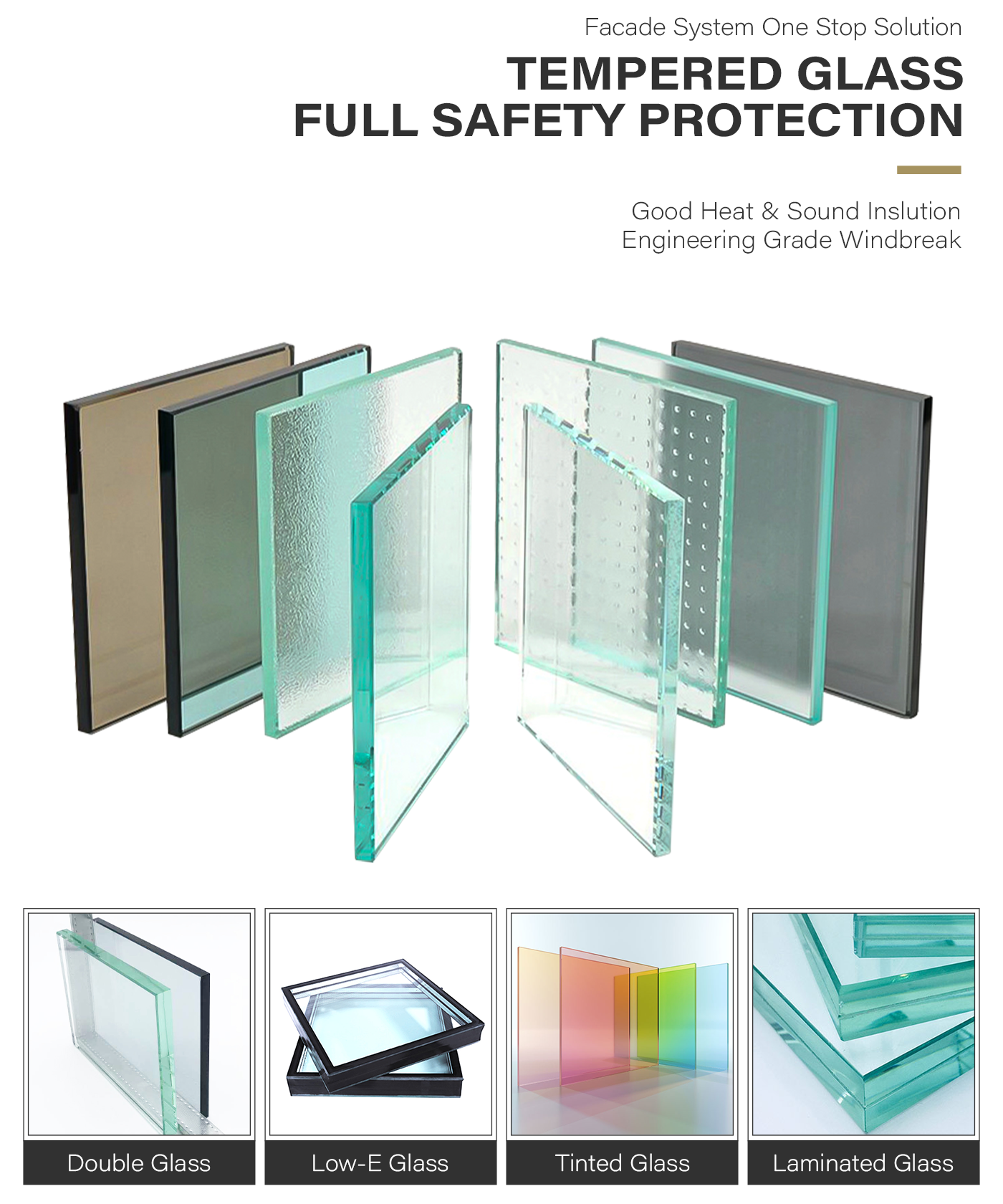

Curtain wall tempered glass should be processed by hot dip. Secondary heat treatment, soaking heat treatment, detonation treatment, "after treatment can be less than 1/1000 of the self-explosion rate" is commonly used in engineering

Packaging & shipping

Free Customized Design

We design complex industrial buildings for clients using AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures(Xsteel)and etc.

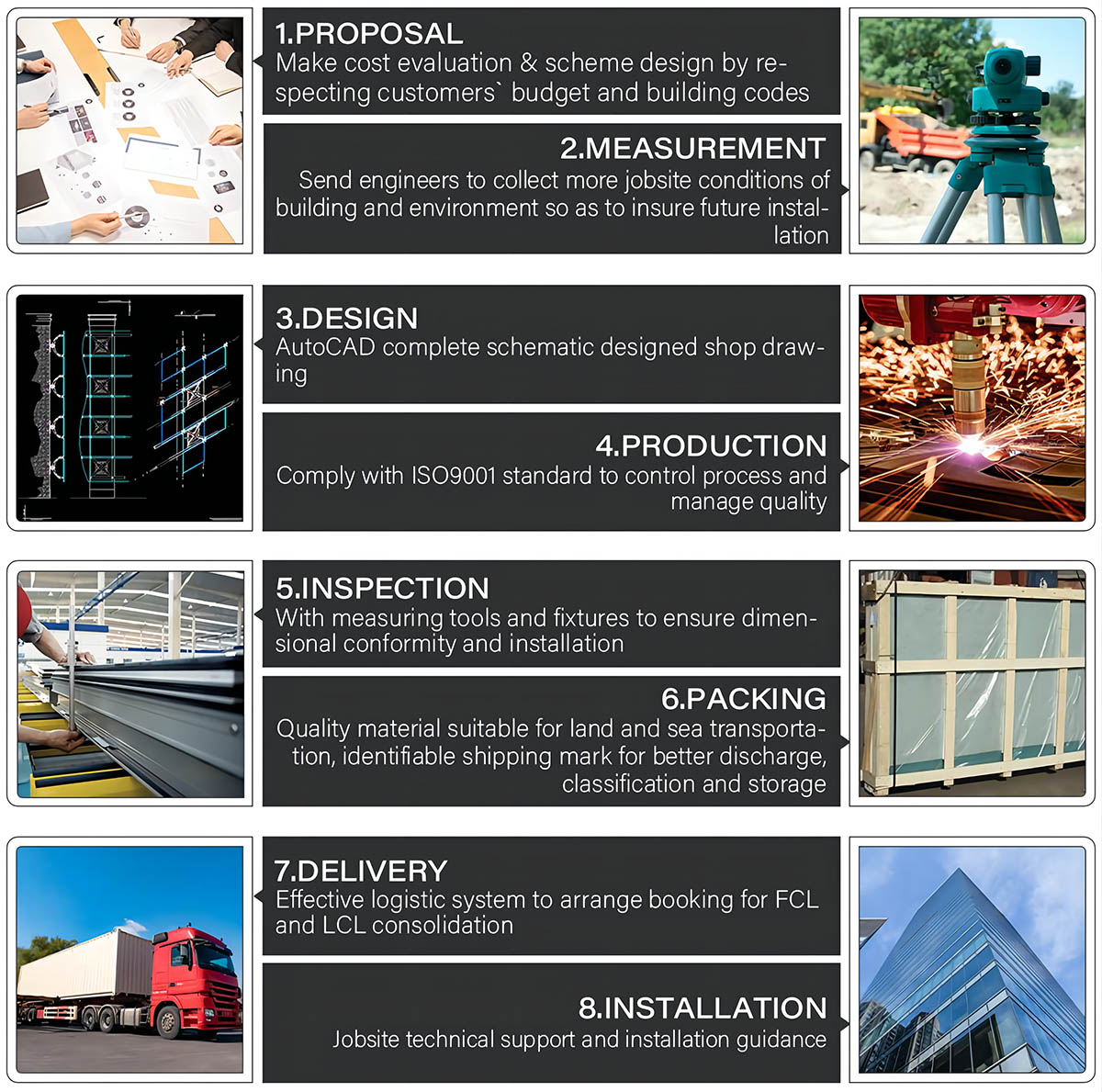

Customization process

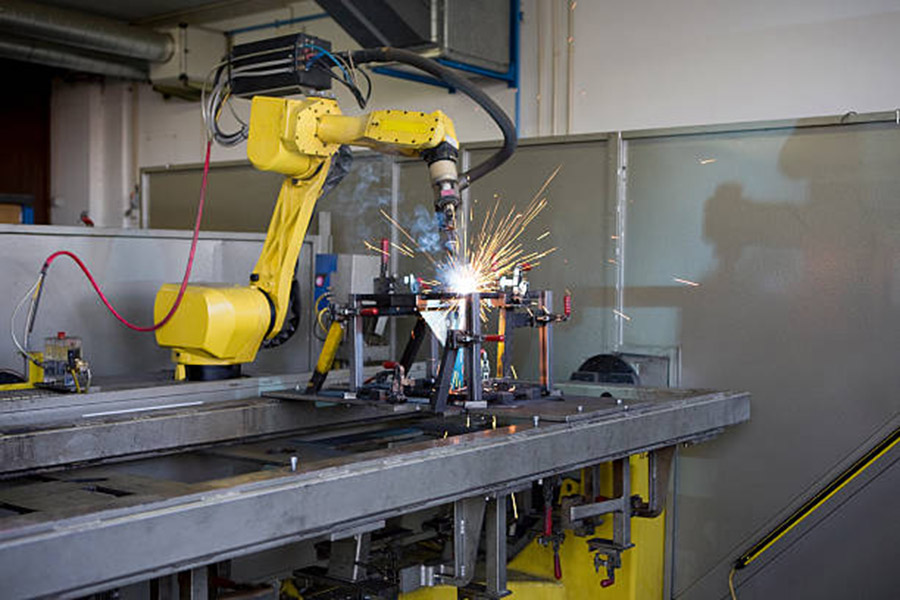

Production Workshop Overview

Iron Workshop

Raw Material Zone 1

Aluminum alloy workshop

Raw Material Zone 2

Robotic welding machine installed in new factory.

Automatic Spraying Area

Multiple cutting machines

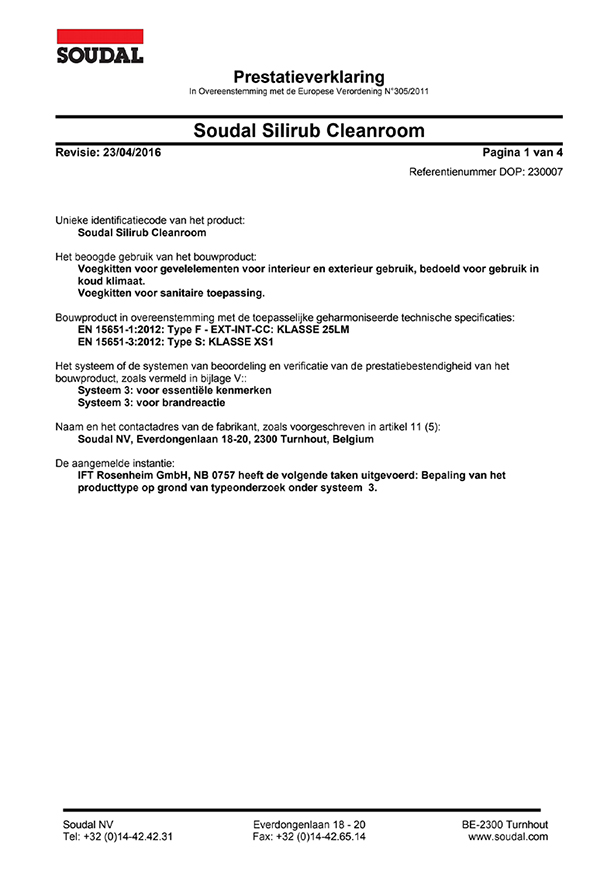

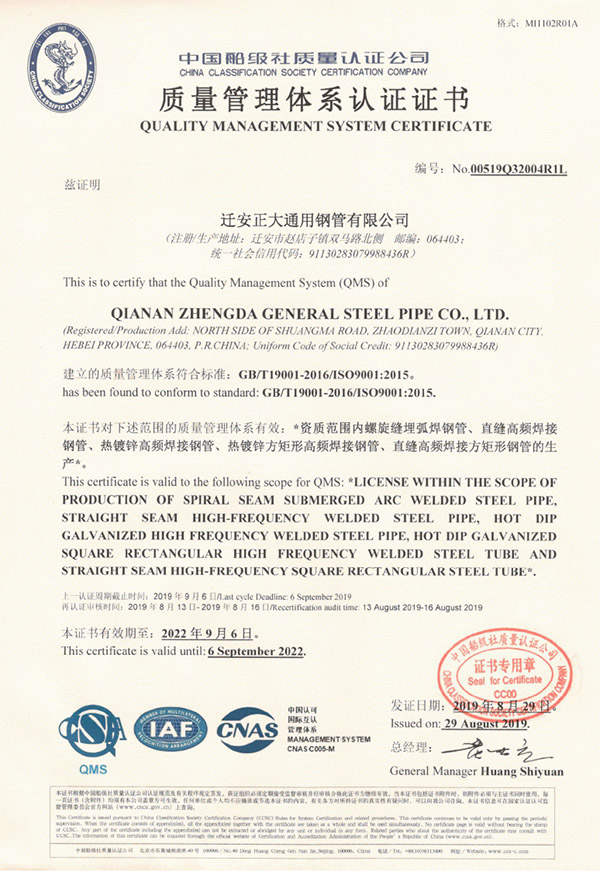

Certification authority

Cooperative company

FAQ

1.What’s your manufacturing time?

38-45 days depends upon down payment received and shop drawing signed

2. What makes your products different from other supplier?

Strictly quality control and very competitive price as well as professional sales and installation engineering services.

3. What the quality assurance you provided and how do you control quality?

Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials, validated or tested materials, finished goods, etc

4. How to get the accurate quotation?

If you can provide the following project data, we are able to offer you with accurate quotation.

Design code/ design standard

Column position

Maximum wind speed

Seismic load

Maximum snow speed

Maximum rainfall