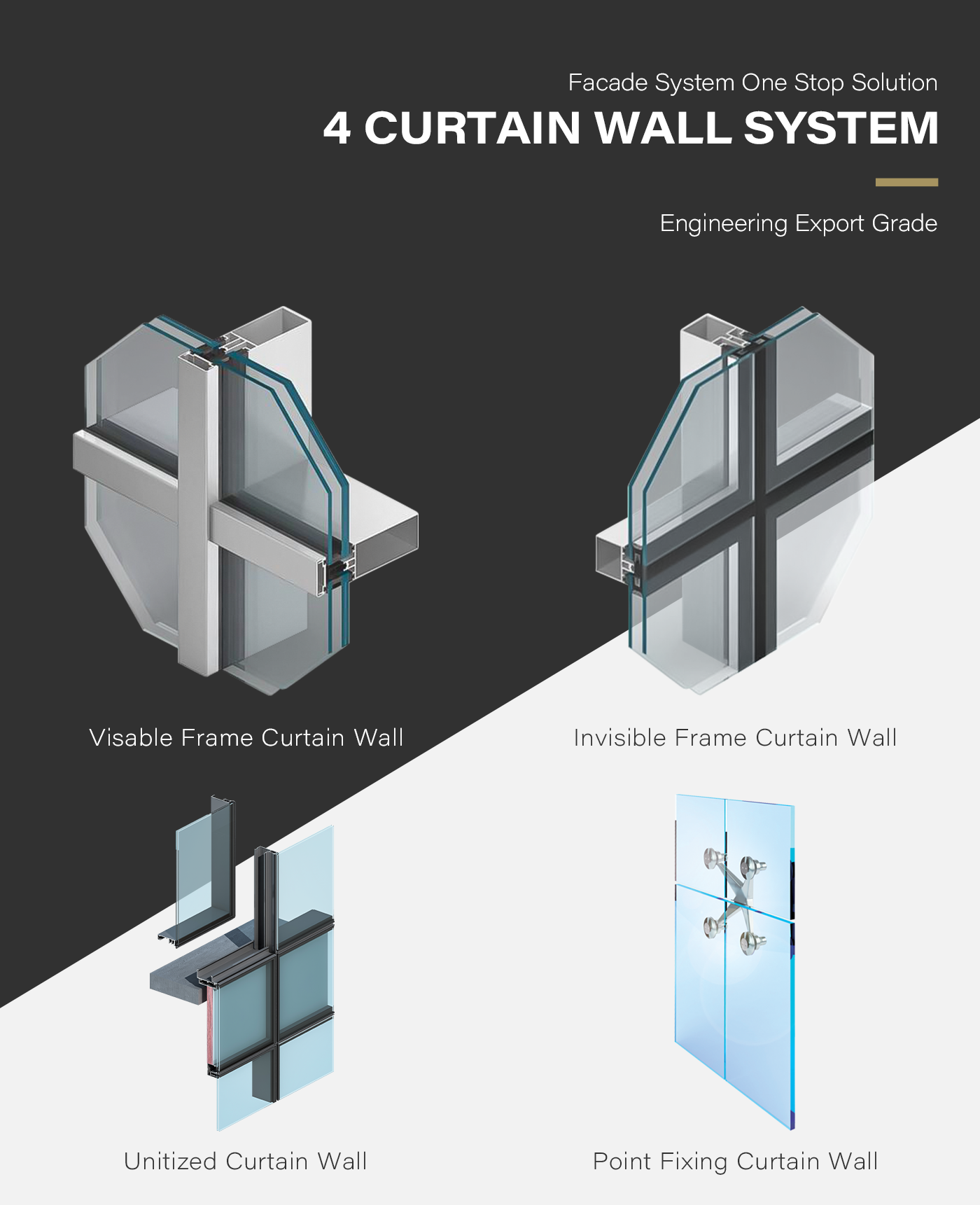

Powder Coated&PVDF Aluminium Stick Frame Curtain Wall Glass Facade system

Main characteristic of stick curtain wall

1.The construction method is flexible and the technology is relatively mature, this curtain wall structure form is widely used at present after more engineering practice tests.

2.The main structure has strong adaptability, and the installation sequence is basically not affected by the main structure.

3.Using sealant joint processing, good water tightness and air tightness. It is preferable heat preservation, sound insulation and noise reduction, also with a certain resistance to inter layer displacement.

4.Panel material unit components are finished in factory, structural adhesive performance is guaranteed.

5.A large number of installation processes are carried out on site, requiring heavy workload of site management.

6.Sealant construction demands is strict, early cleaning, gluing process need high quality requirement of workers.

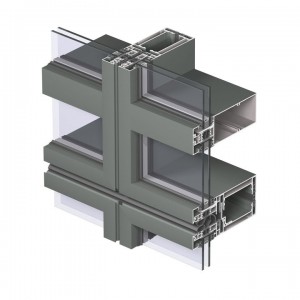

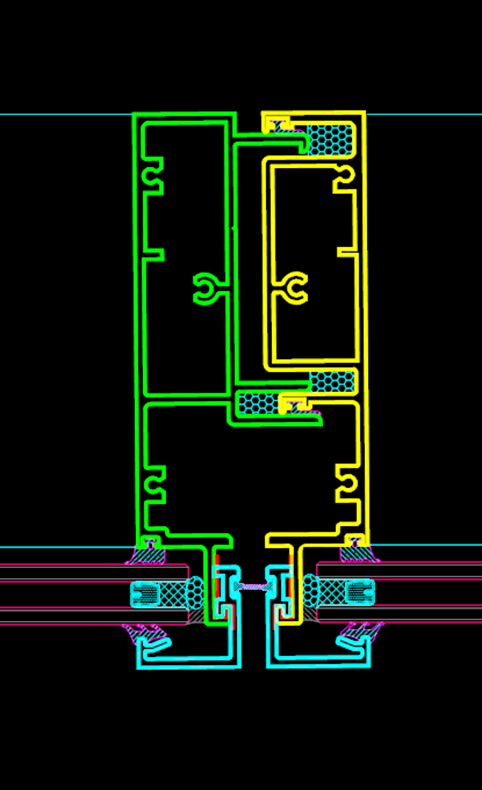

Component fully-hidden frame glass curtain wall

|

Standard products |

Product standardization, serialized design, stable and reliable quality, can meet different requirements. |

|

Structure features |

Positioning installation, distance pressing structure, uniform force on the glass plate; Plate floating connection structure, strong in-plane displacement absorption capacity. |

|

Water tightness Air tightness |

Weather resistant sealant caulking, water tightness and air tightness can reach (GB/T15225-94) I class standard. |

|

Architectural effect |

The facade is flat and simple |

|

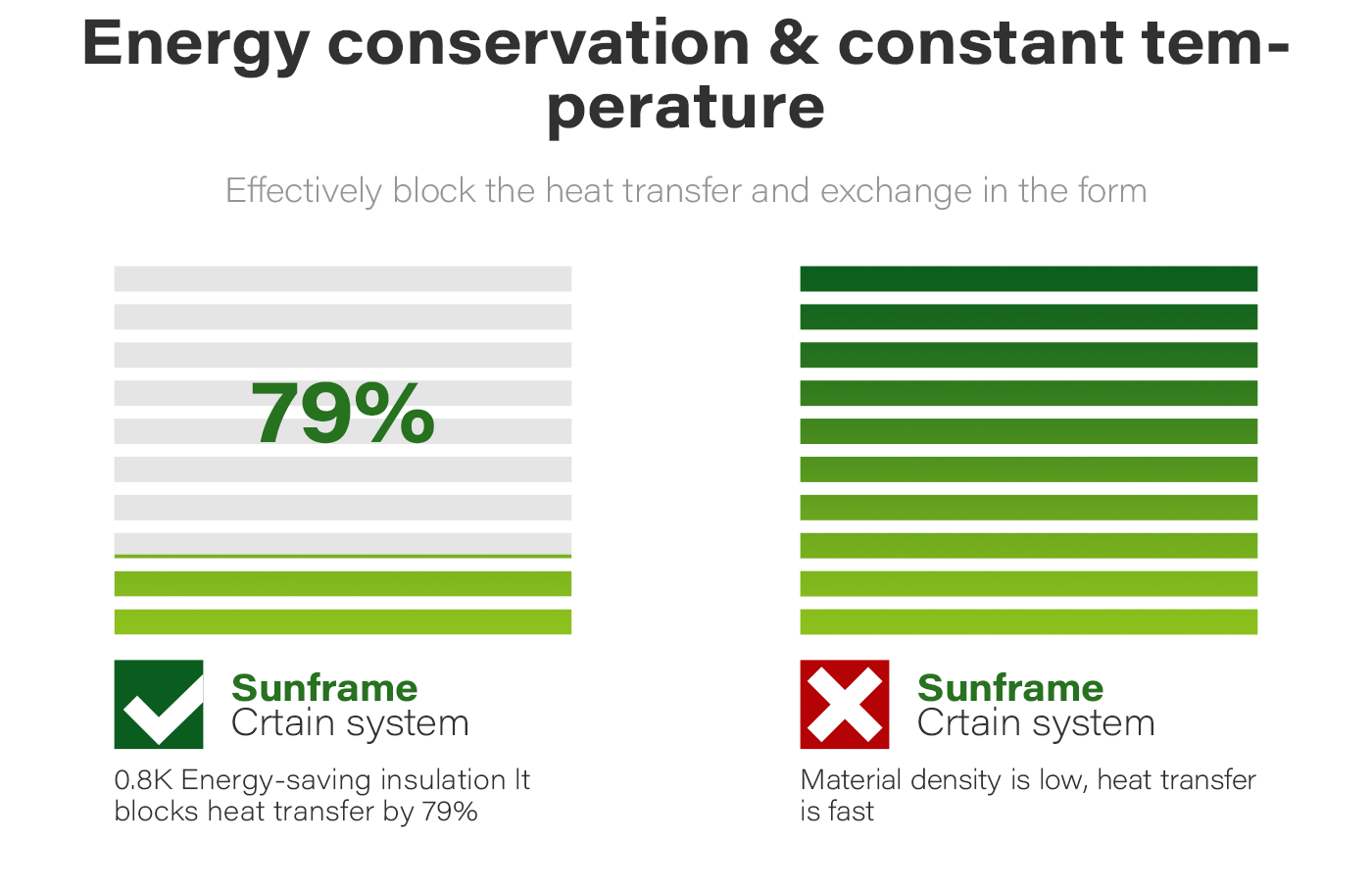

Thermal insulation properties |

Foam rod is used to fill the air cavity, weatherproof sealant is caulked, so that the heat transfer coefficient Uf of the frame can reach 1.7W/m2K. |

Component half-hidden frame glass curtain wall

|

Standard products |

It can be installed and disassembly freely |

|

Structure features |

The glass is mainly subjected to wind pressure by the hook plate on the four sides. The design of structural sealant makes the structure have double safety protection function |

|

Architectural effect |

The outer line of sight is concise and lively, with good permeability |

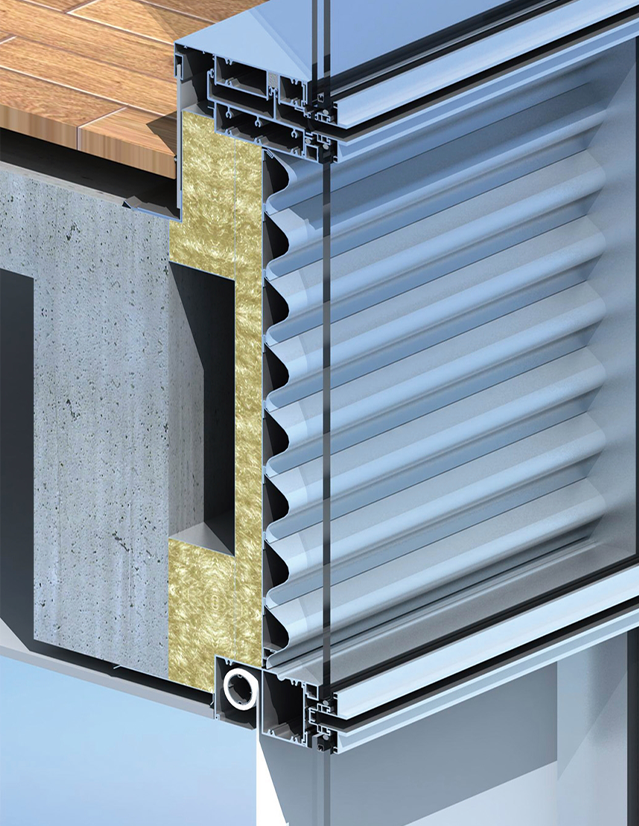

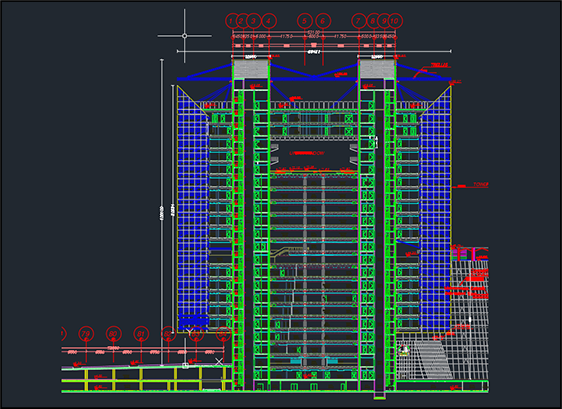

Stick curtain wall

The mullion (or beam) of stick curtain wall is installed on the main structure first, and then the beam (or mullion) is installed.

Mullions and beams form a lattice, Panel materials are processed into unit components in the factory, then fixed on the frame lattice composed of mullion and beam.

The load borne by the panel material unit components is transmitted to the main structure through mullions (or beams).

The common form of the structure is that the mullions and crossbeams are installed on site to form a lattice and the panel material unit components are fixed on the skeleton, The panel material unit component is vertically connected to the column and horizontally connected to the beam and use sealant joint processing to prevent rain seepage and air infiltration.

Site installation

Paste on site

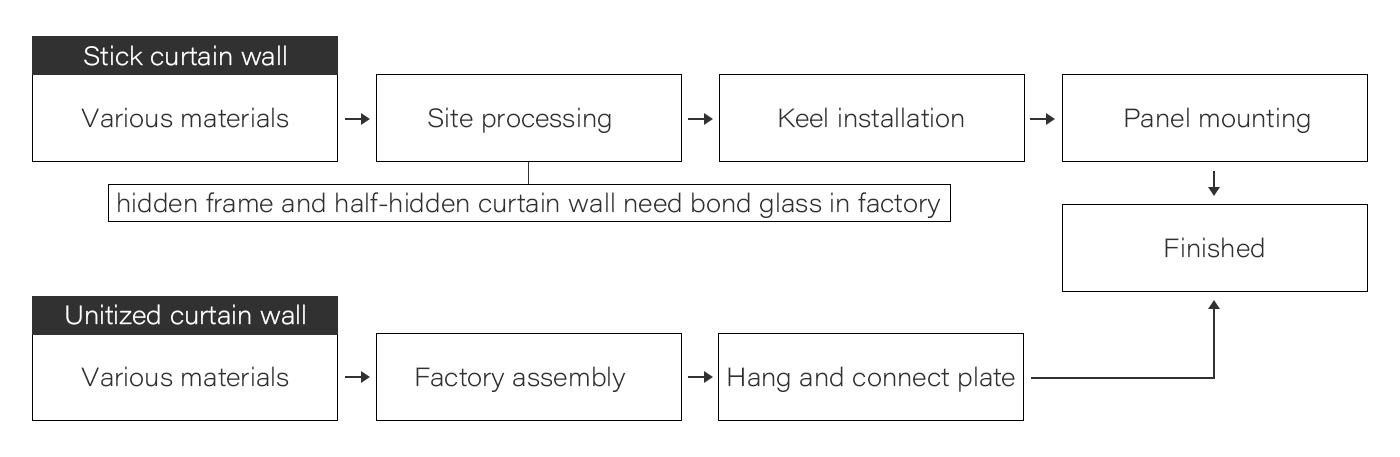

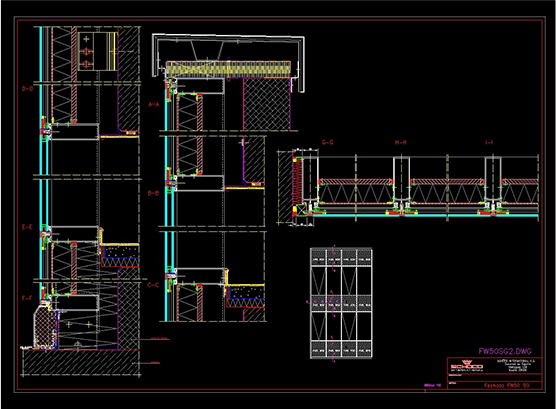

Stick and unitized curtain wall flow chart

Unitized curtain wall lifting

Stick curtain wall installation

Unitized curtain wall lifting

Stick curtain wall installation

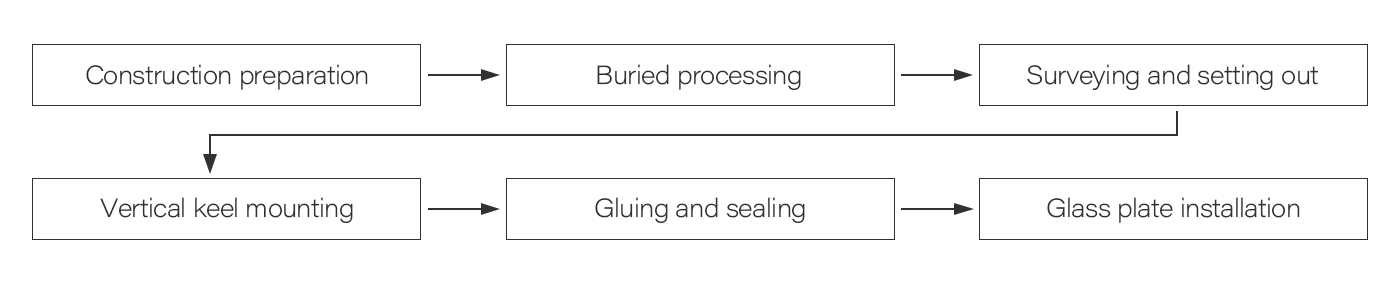

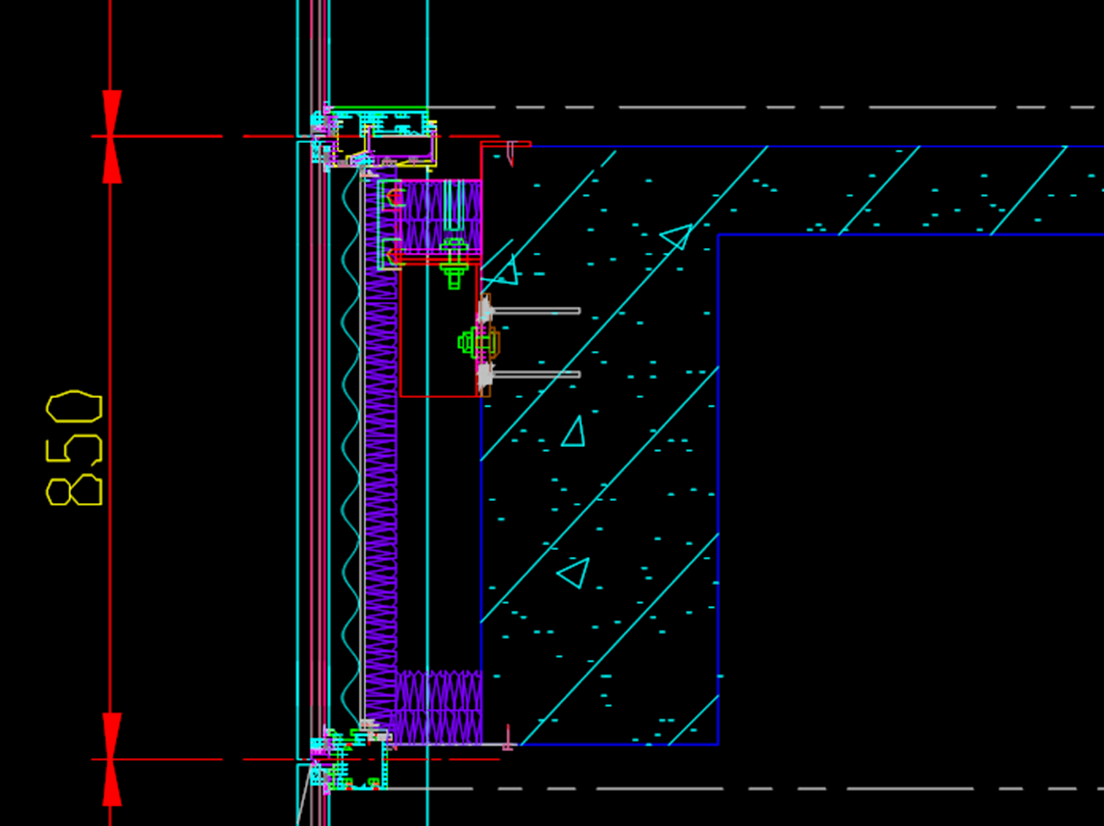

Stick curtain wall construction technology

|

NO. |

Item |

Quality standard |

|

1 |

Column mounting |

The elevation difference between two adjacent columns is less than or equal to 5mm. The distance difference between two adjacent columns is less than or equal to 2mm |

|

2 |

Beam installation |

The levelness deviation of the beam is less than or equal to 2mm, the horizontal elevation difference of the two adjacent beams is less than or equal to 1mm, the distance deviation of the two adjacent beams is less than or equal to 2mm, and the height difference of the main beam within the same height is less than or equal to 5mm. |

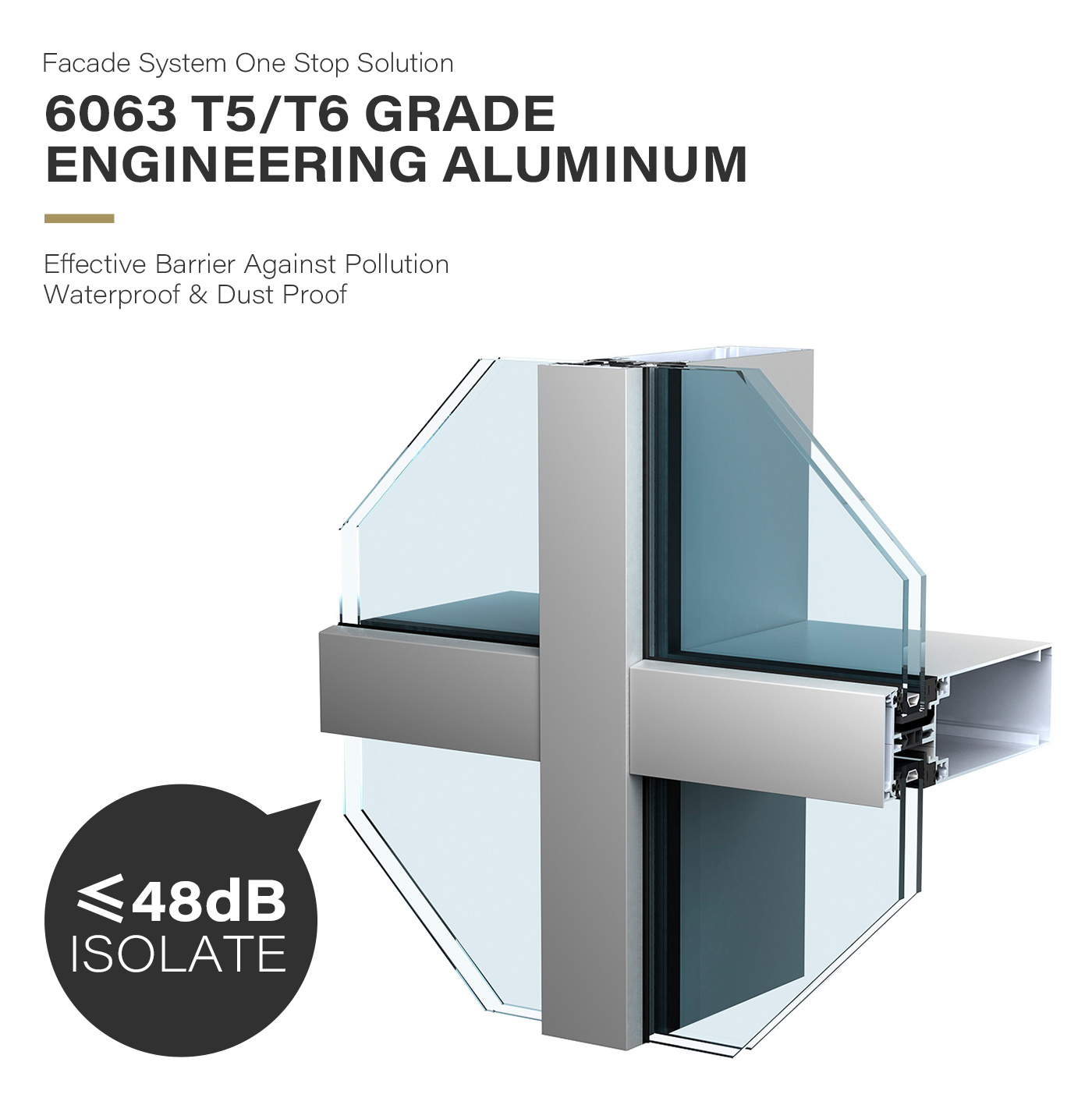

System performance

|

01 |

Sound resistance Rw to 48 dB |

02 |

Wind and water tightness to 1000 Pa (depending on design) |

|

03 |

Column mounting |

04 |

High thermal insulation (depending on design) |

|

05 |

Beam installation |

06 |

High glass weights to 300KG |

|

07 |

View width 60mm |

08 |

Different cover caps on the outside |

|

09 |

Inside and outside color as desired |

||

System performance

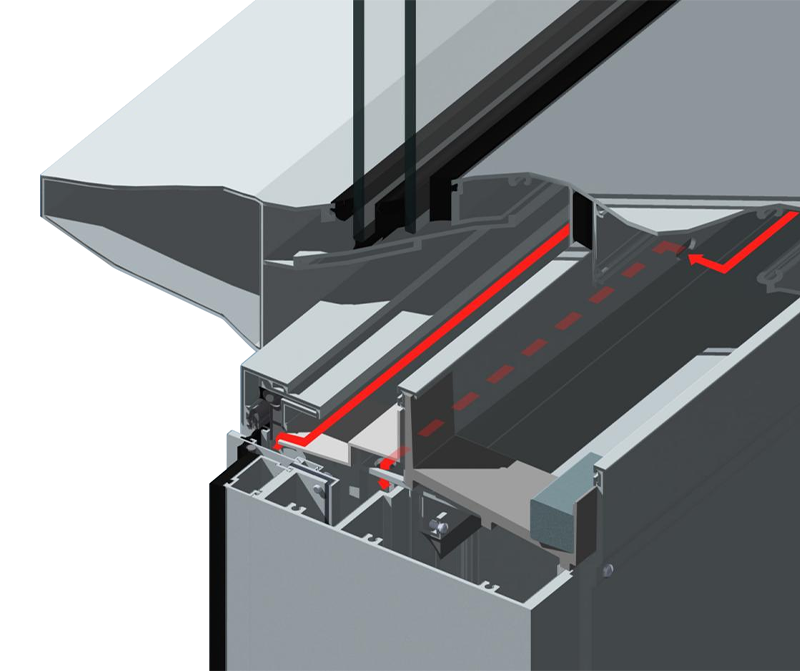

Curtain walls have the primary purpose of keeping air and water out of the building, essentially acting as both a buffer and an insulator. Unlike is continuous windows, which are smaller units and can rely to a high degree on sill flashings to capture frame corner leakage, curtain walls cover large expanses of wall without sill flashings at each glazed opening. Deshion especially patented curtain wall system water penetration resistance high to 1000 Pa.

Curtain wall design performance index

Drainage direction

Stick curtain wall

Waterproofing is generally a single channel seal, it can not form a double seal. The probability of water seepage is 2 times of unitized curtain wall.

Unitized curtain wall

Double channel sealing system, adapt to the main structure of the larger displacement requirements. It can ensure the building has excellent curtain wall performance (air tightness, water tightness, thermal insulation, in-plane deflection, etc.).

*Unitized curtain wall adopts "isobaric principle", waterproof performance is good

Insulation design of unitized curtain wall

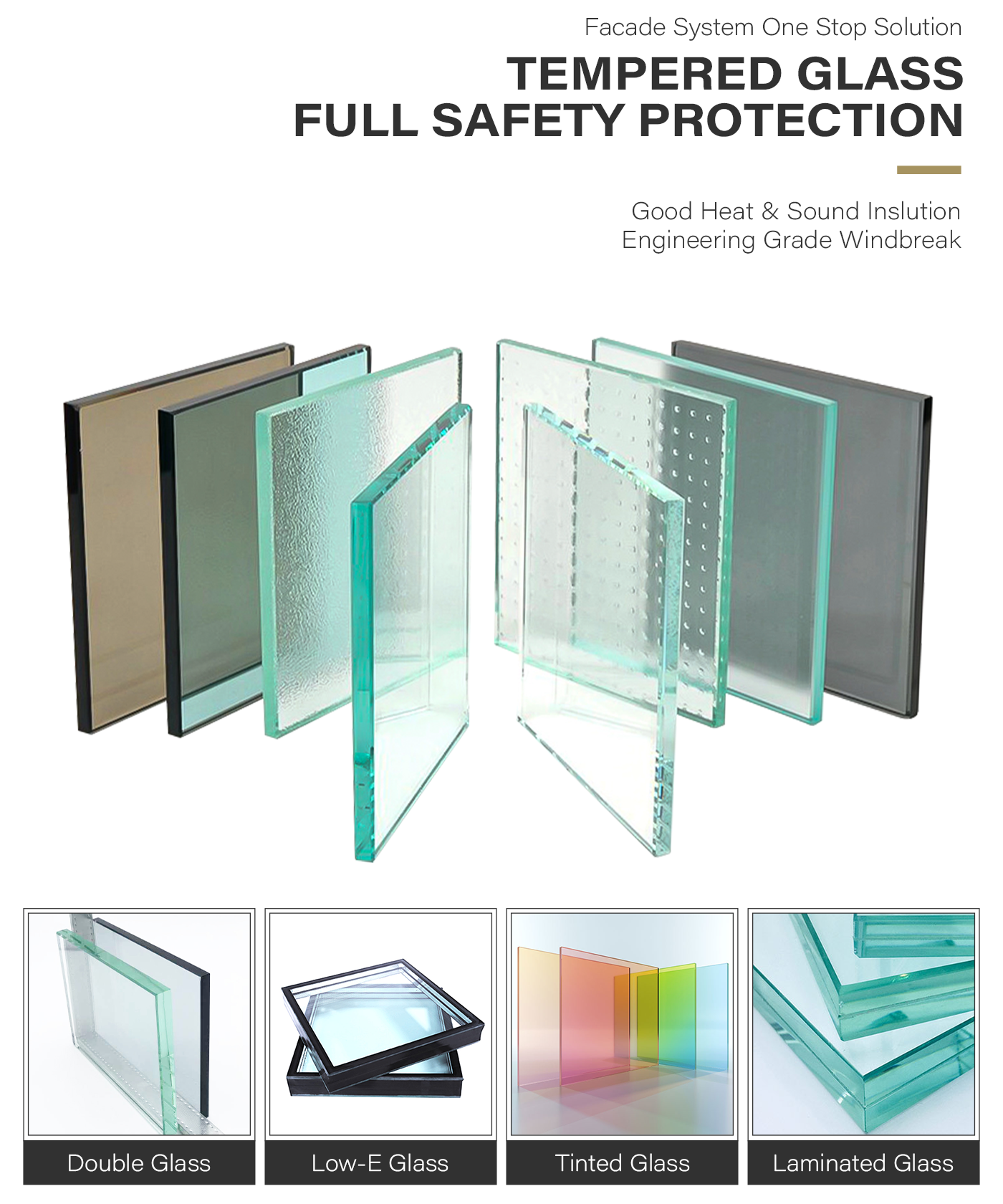

Curtain wall and glass testing

Curtain wall with lighting function requirements, the transmittance reduction factor should not be less than 0.45. Curtain wall with color discrimination requirements, its color perspective index should not be lower than Ra80

The curtain wall shall be able to support its own weight and the weight of various accessories in the design, and can be reliably transferred to the main structure

The maximum deflection of the horizontal stressed member within the span at both ends of a single panel under standard dead weight should not exceed 1/500 of the span at both ends of the panel, and not exceed 3mm

Curtain wall tempered glass should be processed by hot dip. Secondary heat treatment, soaking heat treatment, detonation treatment, "after treatment can be less than 1/1000 of the self-explosion rate" is commonly used in engineering

Packaging & shipping

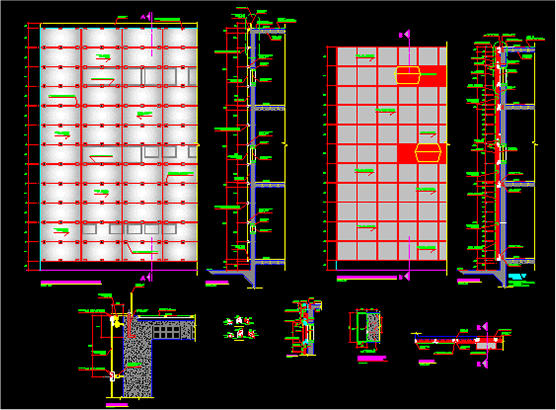

Free Customized Design

We design complex industrial buildings for clients using AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures(Xsteel)and etc.

Customization process

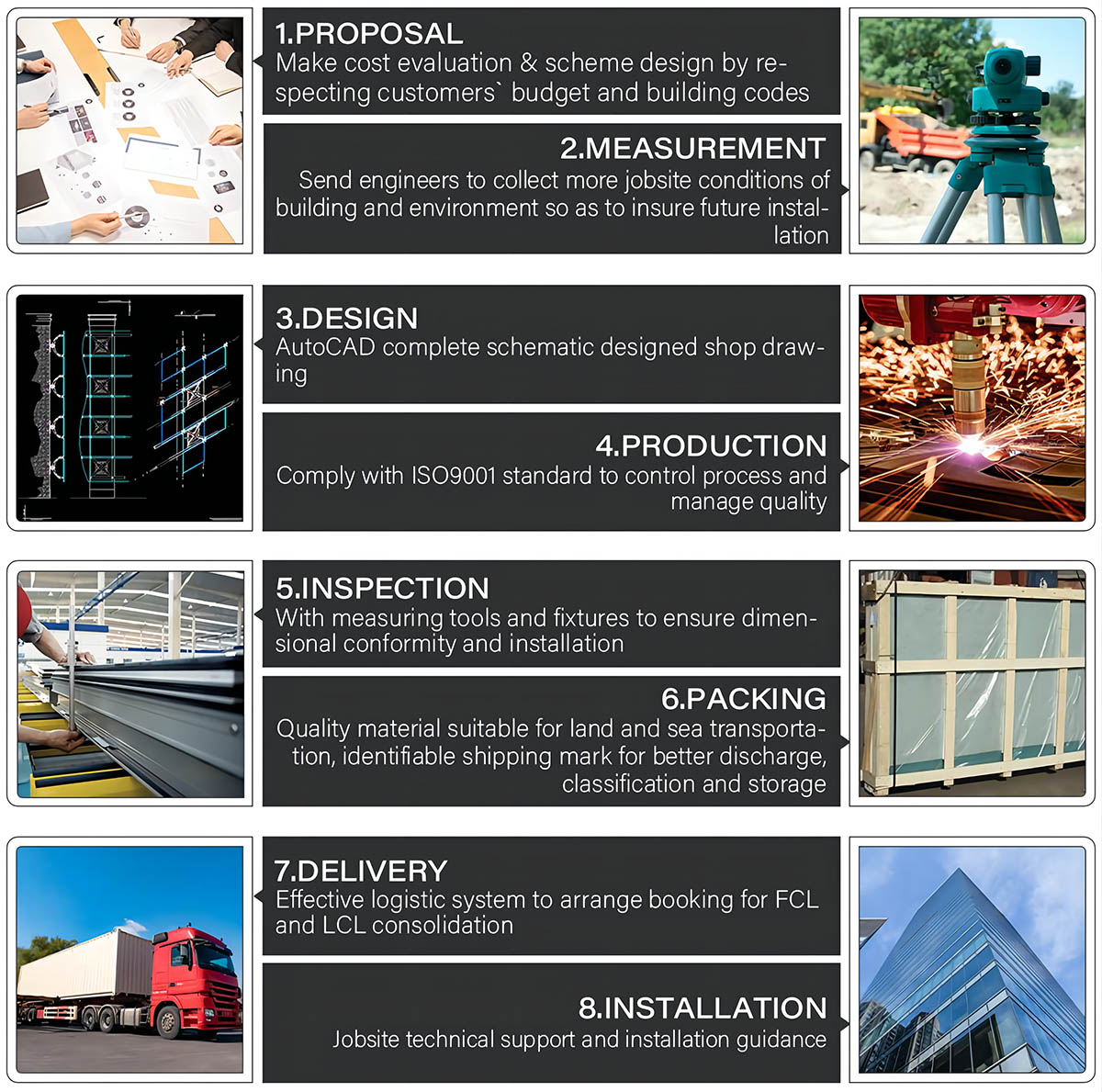

Production Workshop Overview

Iron Workshop

Raw Material Zone 1

Aluminum alloy workshop

Raw Material Zone 2

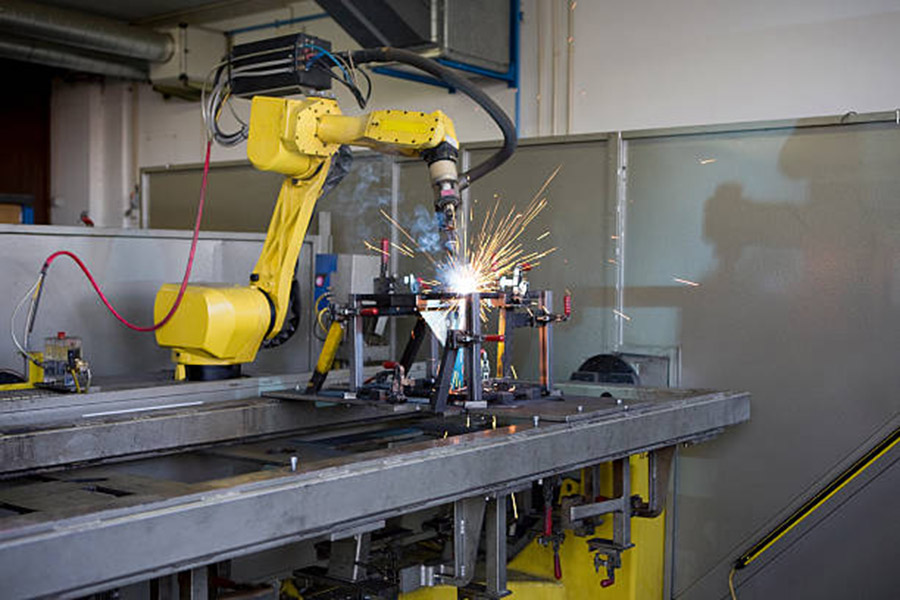

Robotic welding machine installed in new factory.

Automatic Spraying Area

Multiple cutting machines

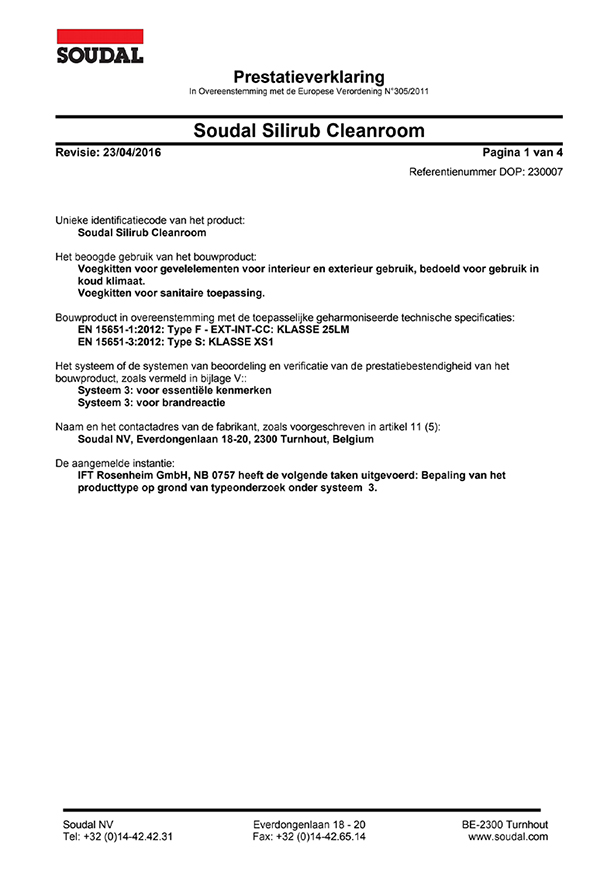

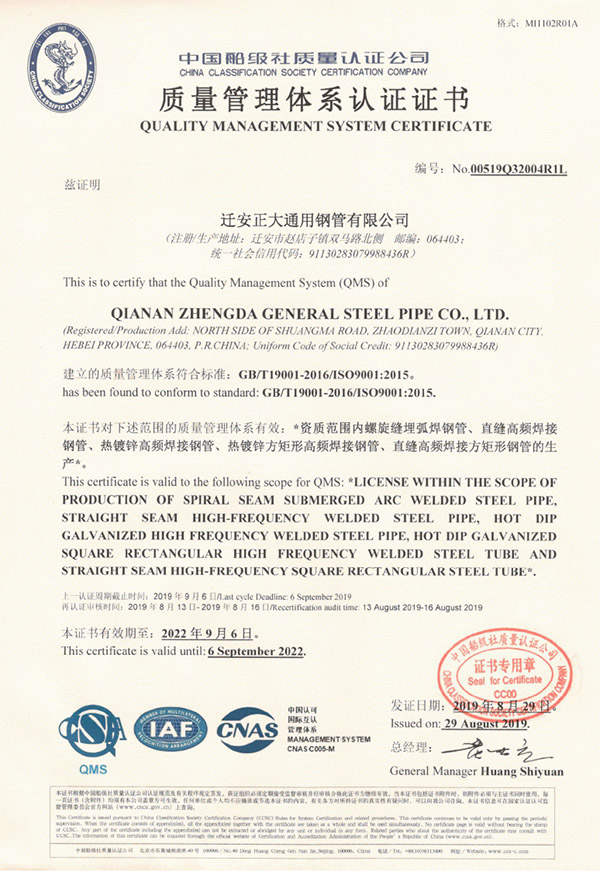

Certification authority

Cooperative company

FAQ

1.What’s your manufacturing time?

38-45 days depends upon down payment received and shop drawing signed

2. What makes your products different from other supplier?

Strictly quality control and very competitive price as well as professional sales and installation engineering services.

3. What the quality assurance you provided and how do you control quality?

Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials, validated or tested materials, finished goods, etc

4. How to get the accurate quotation?

If you can provide the following project data, we are able to offer you with accurate quotation.

Design code/ design standard

Column position

Maximum wind speed

Seismic load

Maximum snow speed

Maximum rainfall